Hello, I'm Pete,

Experienced Mechanical Product Designer

With 20 years of experience, I turn concepts into production-ready products. Offering mechanical design support, prototype development, and full end to end product design. Contact me to bring your ideas to life.

Complete Product design

Conceptual work,

Prototyping and evaluation,

Cost evaluations and BOM creation,

Detail work with integrated DFA and DFM,

Production factory support.

Component design

Functionality and performance,

Reliability and Safety,

Manufacturability and cost-effectiveness,

Design for manufacture and assembly.

Design Support Services

-

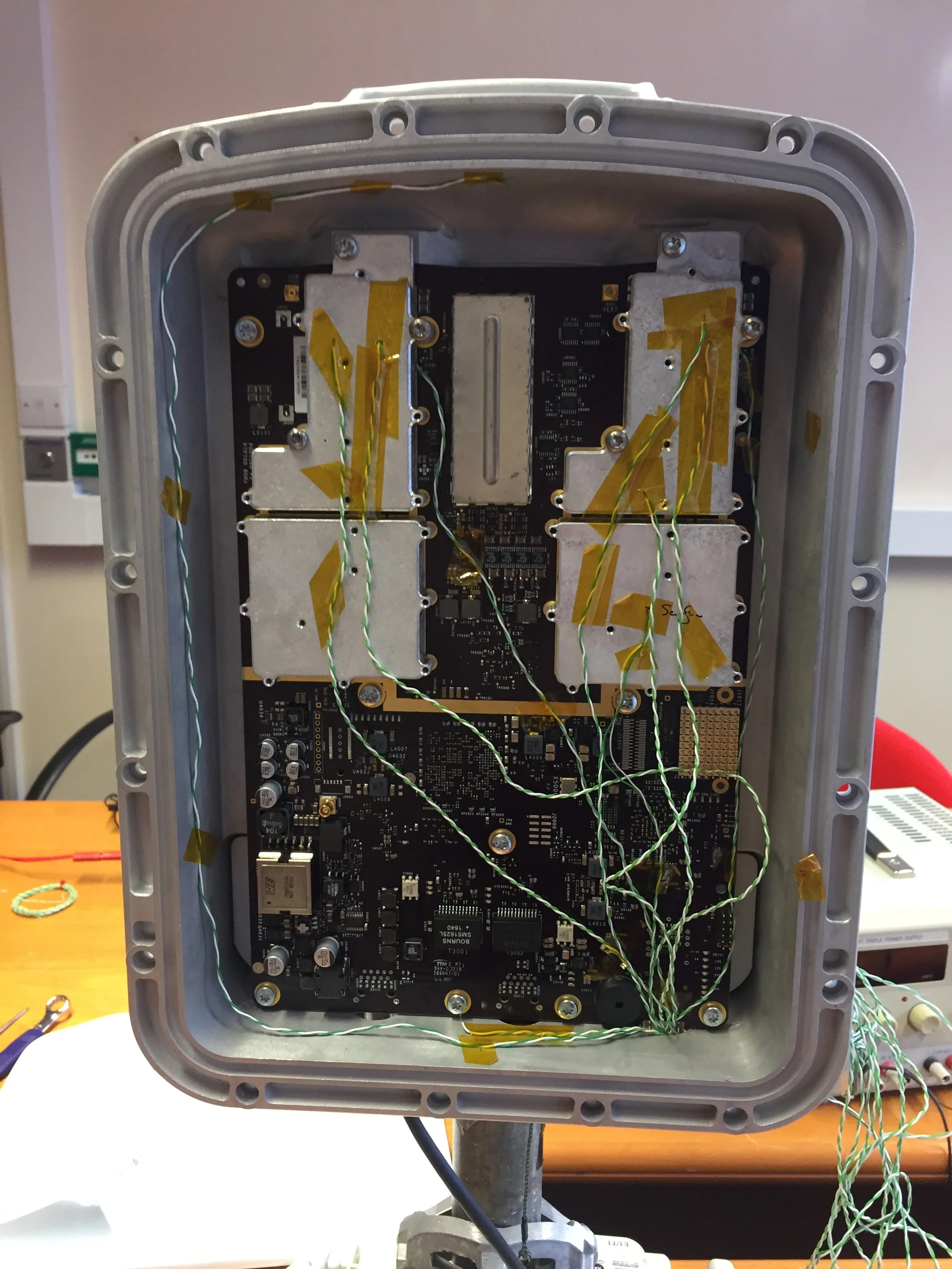

pcba integration

Integration of PCBAs into mechanics, considering thermals, vibration and shock requirements

-

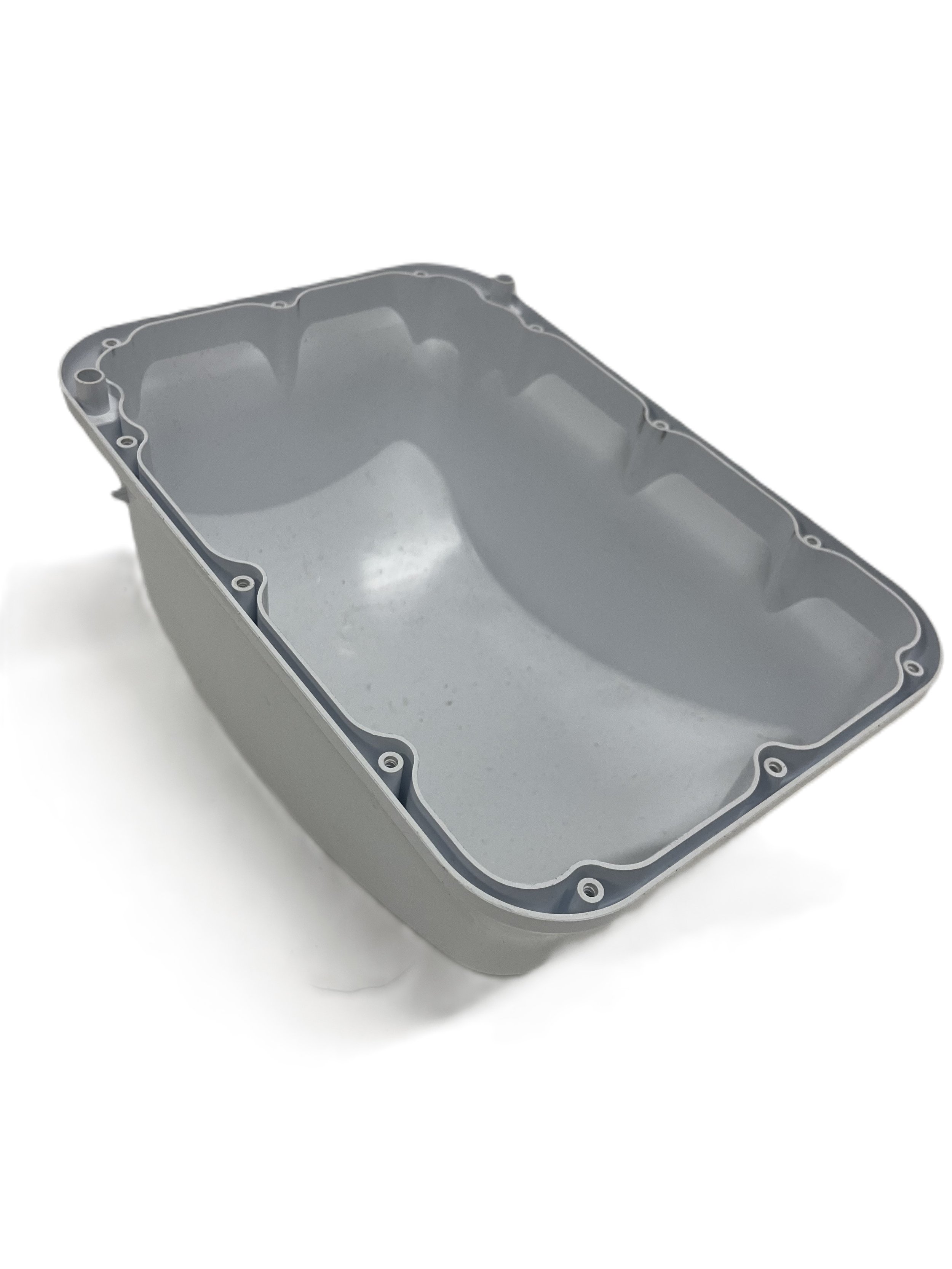

injection moulding Design

Taking a concept and produce an injection mouldable version

-

die casting design

Taking a sketch or existing product and converting to a die cast design

-

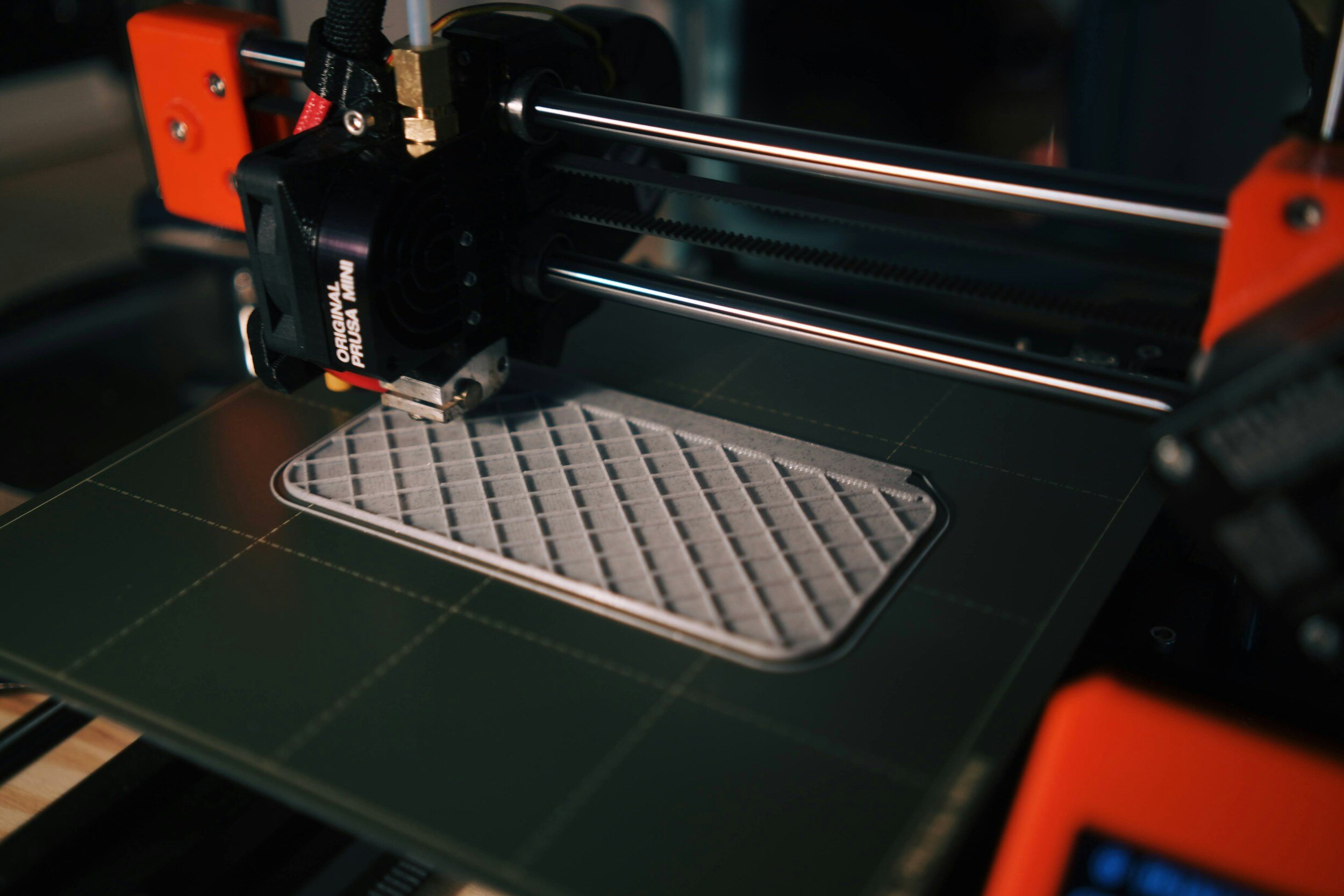

Design for 3D printing

This includes SLS, SLA, FDM techniques

-

3D Print to Production

As volumes increase, there could be a more cost effective way to make the part. We can investigate for you.

-

integrating 3d scans

Working with scanned data to form stable 3D ,models that integrate with existing components.

-

2d drawing updates

Clear updates to existing drawings with revision control

-

sheet metal Design

Using 3D CAD to create sheet metal models that can be flattened for the metal net shape.

-

Design for harsh environments

IP rated designs that have yerrs ef real life testing.

-

Production fixtures

Fixtures for product test or to aid product assembly process

Concept to production services

-

concept generation

Based on a brief, often includes industrial and mechanical design inputs with the end user in mind.

-

bill of materials costing analysis

Tracking product costings in a BOM structure

-

prototyping manufacture and evaluation

Whether it is 3D printed, machined from billet or vacuum cast.

-

sourcing components in the fareast

Working with reliable suppliers to offer quality components at competitive prices.

-

support with factory setup

working with contract manufacturers to define reliable manufacturing processes and production lines.

design analysis & rendering services

-

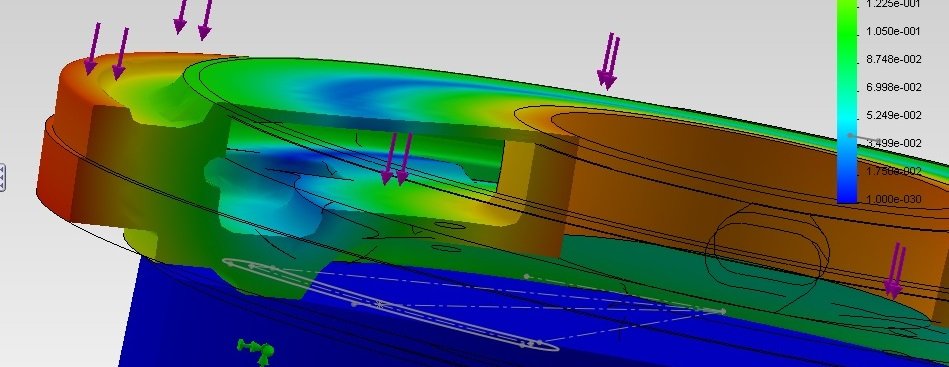

stress / strain analysis

Component optimisation through the use of FEA

-

Thermal studies

Specifically focused around PCBA thermal integration with mechanics

-

Product Rendering

Product renderings using Keyshot / blender