v1000 - wireless communication device

This was a complete mechanical design consisting on 14 custom components made using different manufacturing techniques like injection moulding, die casting, die cutting, sheet metal with progression tooling and machining.

Project Highlights:

Thermal management of power dense components. One challenging component measured 2.2x2.6mm had an exposed die and used 3Watts. The lower we could keep the temperature the better the performance.

Design with cost and volume in mind. Automated tooling and assembly processes used to keep cost to a minimum.

Rendering of the front of the product

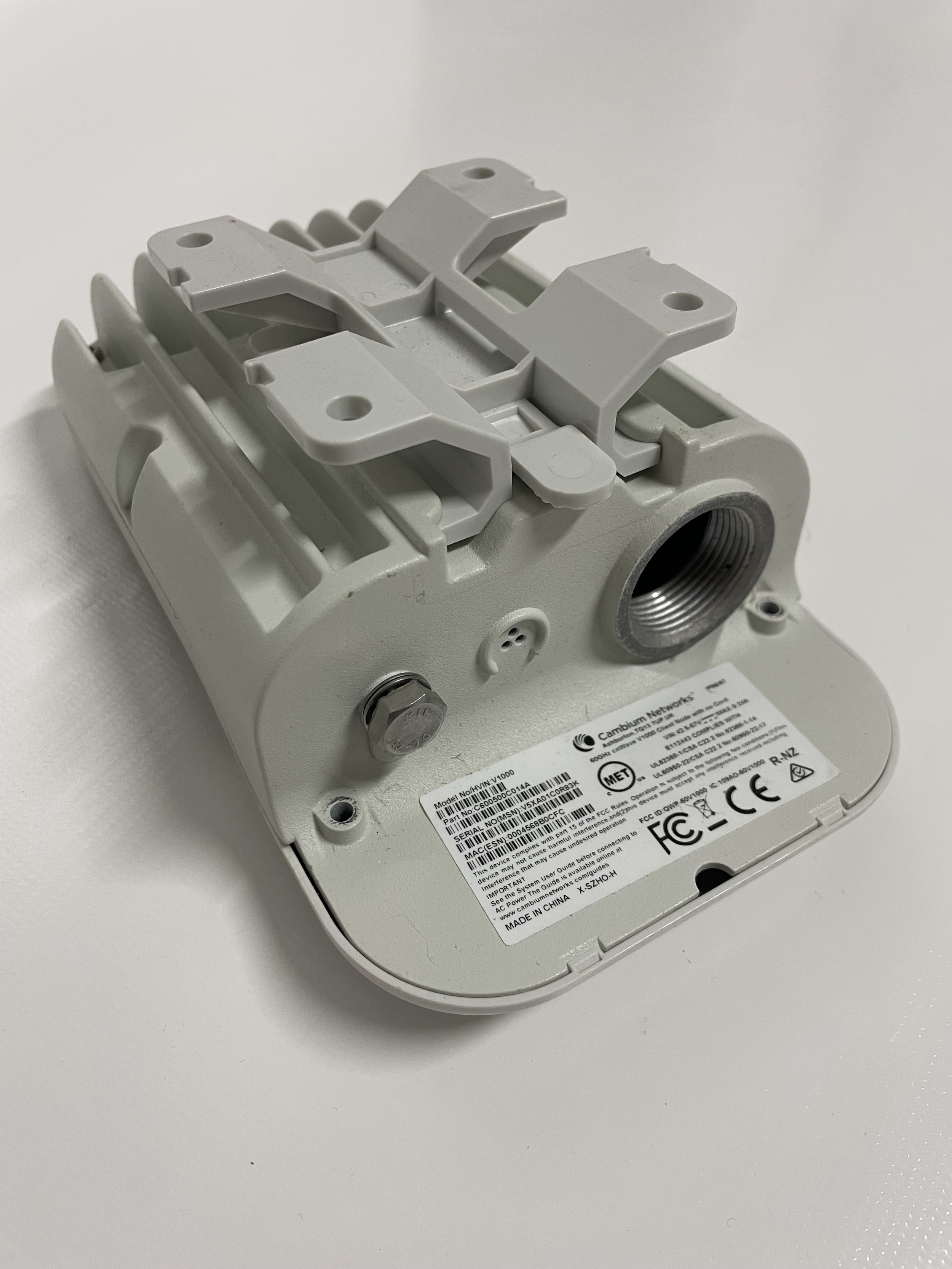

Back of the product showing the enclosure die casting

Bracket - injection moulded.